Roman blown glass compositions:

following supply patterns in the manufacturing chain

Bruce Velde

Directeur de Recherche Emérite CNRS

Laboratoire de Géologie, CNRS UMR 2385 – ENS (École normale supérieure) Paris (France)

Roman glass objects were produced using a two step process: production of raw glass material in the Near East and production of blown or poured objects in workshops throughout the Empire. An obvious question then concerns the distribution of the raw glass to local manufacturing sites. Was semi-finished glass traded as a bulk commodity to be stocked and redistributed on demand or was it supplied directly on demand to the workshop from the producing region? We consider chemical data indicating a probable production – transport – workshop use path. Data for individual workshops appears to indicate a continued supply of a specific raw glass composition. This suggests a commercial system of supply on demand of a given material. Overall it indicates a centralization of raw glass production that was maintained for 400 years or so. Such a system is unusual in the annals of economic history. In this instance innovation comes from a change in the organization of the production cycle, breaking it into different parts, which allows a significant change in the way things were produced. The efficiency of producing a raw, semi-finished glass distributed to different sites for final production of objects allowed a significant gain in productivity with high standards for the finished product. This innovation changed the use of glass over the Roman Empire.

Les compositions de verre soufflé romain :

des indices révélateurs de la chaîne de fabrication.

Les objets en verre romain étaient produits en deux temps : fabrication du verre brut au Proche-Orient, puis production d'objets soufflés ou moulés dans des ateliers à travers l'Empire. La mise à disposition de verre brut dans les sites de fabrication locale devient une question fondamentale. Le verre semi-fini était-il commercialisé comme une matière première en vrac, stocké et redistribué, ou était-il directement fourni à la demande d'un site de production local ?

Les données d'analyses chimiques sont utilisées comme sources pour repérer une chaîne de fabrication : « lieu de production possible – transport – atelier de transformation ».

En effet, les données réunies pour des ateliers locaux individuels indiquent la fourniture d'une qualité spécifique de verre brut. Ceci signe bien un système commercial de fourniture à la demande pour un matériau précis. De manière générale il révèle une centralisation de la fabrication de verre brut qui s'est maintenue pendant 400 ans environ, un système tout à fait inhabituel dans les annales de l'histoire économique.

Dans un tel contexte, l'innovation apparaît dans le changement d'organisation du cycle de production, le rompant en différents lieux et permettant des changements conséquents dans les manières de faire.

La production d'une matière première brute centralisée et répartie ensuite vers des centres régionaux garantissait des gains de productivité importants ainsi que des standards de qualité élevée. Les transformations vont bouleverser l'usage du verre dans tout l'Empire romain.

Introduction

Over the past decades, a large amount of information has been amassed concerning the composition of Roman glass objects and a reasonable number of studies show compositions for material coming from individual glass workshops. Early suggestions that a raw glass semi-finished product re-worked to be made into blown glass objects of a more or less common source (Velde and Sennequier, 1985) has been confirmed by more recent publications (see La Route du Verre, Maison d'Orient, Lyon, 2000). Sites probably somewhere along the Mediterranean coasts of present-day Egypt, Israel, Syria and Lebanon produced sodic glass from mineral sources of natron coming from a site near Alexandria, and using dune sands along the Levantine coast as a source of silica. The composition seems to have been first used systematically by the Hellenistic Greeks (Dussart and Velde, 1990) as ancient texts attest the use of dune sand near Sidon (Strabon quoted by Toutain, 1927, p. 127). There seems to have been continued use of the same general sources of raw materials until about the 5th century AD (Aerts, 2003; Foy et al. 2000). Exceptions are found in later Roman raw glass productions found in the area near the source of soda, Wadi Natron (Nenna, 2000 and 2005) where, by looking at the averages for the analyses one can deduce that higher amounts of soda in the raw glass materials reflect differences in the production method and lower impurities of alumina and calcium indicate different sand sources.

The raw glasses were furnished to secondary production sites over the Roman Empire and fashioned into different objects ranging from window panes, to bottles or table ware. Raw glass ingots have been found in numerous archaeological contexts (Foy et al., 2000 for example). Given the highly ordered and efficient economic system of the period, one can attempt to investigate how the raw glass, produced for the most part in the Near East, was procured by the end term production agents, the glass blowers. Did they take what was offered to them by local secondary dealers from intermediate warehousing facilities or could they place an "order" for material from a particular production site with a given composition and working properties? The following study attempts to elucidate some of the aspects of supply and use in the glass making and production chain.

Extensive work has been done in trying to establish compositional groups for Roman glass (see Foy et al. 2003 for example). The method used by these authors to establish these groupings is accomplished by multivariate analysis of the chemical data which is a very powerful tool, taking into account simultaneously all of the elements analyzed. However, the size or definition of the compositional ranges used to establish the groups is determined by the operator of the statistical analysis system and the resultant groupings are not necessarily based upon specific functional, archaeological relations which could be established by archaeologists. For example, changes in production method of raw glass over time might form several groups in the analytical analysis result or perhaps one continuous trend in compositions which will not be seen by these statistical methods. Changes in supplier over time might create different compositional groups for the same finished product. For example, an attempt to establish variations for a particular type of glass production, the Frontinian barrel bottles found in northern Europe (notably Germany and France) by Velde and Sennequier (1985), indicated shifts in composition as a function of the region where the objects were found as well as their age. However, no direct production site could be established for all of the bottles and their overall compositional variation is sufficiently large to suggest possible multiple production sites.

A basic question which can be asked is: what does composition mean for a given production or production site? We propose to use simple compositional variation diagrams for objects from several glass blowing workshop sites in order to investigate the possible relations between supply and use of raw glass in manufacturing objects at various sites in the Roman Empire. The compositions of glass fragments from the workshope are compared to variations in glass objects found at different sites in three large Gallo-Romancities in order to give a perspective on the variations that are possible for roamn glass and those seen for a specific production site. Using these local atelier variations we wish to investigate the significance of compositional variation in raw glass related to production at a specific site over the period of activity of the atelier.

Study

Evidence of a supply chain

A question can be posed initially: do we have information which links a production site of raw glass, its transportation and use to produce finished products?

Finished Products

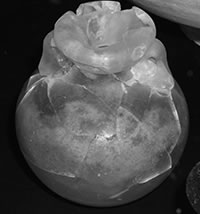

Figure 1. Small aryballe bottle showing fracture aspect of the samples studied. © All rights reserved.

The data considered here are from two sources for objects from archaeological sites relatively near each other in north eastern France; Arcis-sur-Aube, 3 samples in two tombs, reported by Cabart (2004) and fragments of 16 objects from cremation sites at Pontpierre (Moselle) (Cabart, 2005). All samples were selected for their rather special physical aspect producing clear and un-colored objects initially having a distinct whitish tinge instead of the frequent bluish or yellowish coloring of Roman blown glasses. Further, the samples had a very particular fragmentation aspect, where the rather thick (several millimetres) glass broke into small (5-10 mm) diameter roughly equant fragments (Figure 1). Such an aspect can be seen for example in the Begram, Afghanistan samples, some of which were analyzed by R. Brill (Brill, 1999) presently exhibited in the Guimet Museum in Paris. The objects are whitish in color or colored cobalt blue and showing the characteristic tendency to fragment as those in Eastern France described above and shown in Figure 1. Some the analyses reported indicate rather high soda contents as do the samples from Eastern France as we see below. However it is not possible to identify a given object with the analysis given by Brill.

In general, the samples selected for their physical alteration characteristics are objects used for storage (and shipping) of liquids and objects used for table service. By stylistic and archaeological information the samples can be considered to be late second and third century objects. The chemical analyses of the samples with unusual alteration qualities show a specific composition (Annex).

Establishing the supply chain

The chemical compositions of these Eastern French finished product materials can be compared with published data for Wadi Natron raw glass considered to be earlier than 4th century (Nenna et al., 2003; Nenna et al., 2005, Foy et al., 2003) and analyses of samples of transported raw glass ingots from the 3rd century Embiez shipwreck (Foy et al., 2004, Foy et al., 2005) off the French Mediterranean coast.

It is most useful to observe the sodium and the calcium content reflecting variations in the proportion of the fusing agent (sodium) relative to the amount of the sand component using Ca as a standard and constant impurity in Roman glass sand compositions, (Figure 2). Within the sand components differences in the calcium to the alumina content indicate differences in provenance of sand resources (Figure 3). The fusing agent, sodium, is almost impurity free.

Figure 2. Na versus Ca content fusing agent versus sand content.

2a) Roman-east France and Wadi Natron

2b) Embiez and east France

Figure 2a indicates general chemical variations of Roman glass, compared to those of the Eastern French samples for the relations of fusing agent natron (natron was essentially pure sodium carbonate, Na2CO3 analyzed as Na2O) and sand (which is usually nearly pure quartz, SiO2) indicated by a calcium impurity (CaO).

We can put these comparisons in perspective by using a reasonably large data base (425 samples) of glass analyses from the northern Roman Empire over a five century span, thus covering much of the possible variation in Roman glass composition (compilation of analyses taken from the sources quoted below). It can be seen that the Pierrepont – Arcis-sur-Aube type samples are at the edge of the range of Roman glass compositions, being low in calcium and sodium elemental abundance shown in Figure 2b. The Wadi Natron raw glass compositions are similar but not identical to the other two sets of analyses, shipwreck and finished products from Eastern France. The Wadi Natron, Embiez and eastern France samples investigated here appear to be on the edge of the range of Roman glasses presented. Raw glass was most likely produced in this area from the 1st century to the 3rd century (Nenna et al., 2000; Nenna et al., 2005).

The second comparison can be made using the variables associated with the sand component itself, the impurity elements calcium and alumina (Al2O3) as seen in Figure 3. This allows us to identify differences in this natural resource. Here again the content of the Pierrepont and Arcis-sur-Aube samples are rather distinct from the majority of Roman glasses. The east France and Embiez shipwreck material are both low in calcium and low in alumina compared to the general Roman glass composition (Figure 3b). Also the Wadi Natron raw glasses are low in alumina and calcium and the Eastern French glass as well as the Embiez shipwreck raw glass fall within the Wadi Natron compositional range (Figure 3c). All three sets of data are distinct from the general glass compositions in the same manner.

We postulate that the archaeological glass objects found in eastern France were produced from Wadi Natron type raw glass and that the trace of their transportation to the producer of blown glass objects was in the Embiez ship wreck. The ages of the eastern France finds and the Embiez shipwreck near Marseilles are similar, 2-3rd century and the Wadi Natron material is dated as earlier than 4th century. It thus seems logical to consider that these high sodium glasses from late Roman production came from the Wadi Natron Egyptian area and not the Levantine coast.

Other glass material found in the Embiez ship wreck indicates the same composition for blown glass objects but different compositions for domed shape window glass.

Figure 4. Sketch map of the area indicating raw glass production, transport and use. © All rights reserved.

The geographic disposition of these different sites in the supply chain is shown in Figure 4.

Thus it appears that here we can establish a production site, transportation and use supply chain.

Interestingly, similar glass objects, in their manner of weathering and fracture, can be found in the Musée Guimet in Paris, coming from Begram in present day Afghanistan. Analysis of several of the objects by Brill (1999) of 1st and/or 3rd century age show high sodium content suggesting Wadi Natron type composition. Although we cannot identify whether or not the specimens on display correspond to a given published analysis, the shapes and decors of the glass objects indicate a local production. Hence here the Wadi Natron raw glass was sent in quite another direction from that in northern France.

How did the system work?

In order to produce glass from its raw materials, sand and fusing agents, one needs glass. Glass making (production of a liquid silicate melt) is a two step process where the raw chemical components are mixed and fired to a high temperature forming a frit, which is a incompletely melted assemblage of the components. The frit is then re-heated in the presence of glass (a "frozen" silicate liquid) which melts and incorporates the frit into the molten mass. This operation requires a separate furnace from that needed to produce frit from raw materials sand and fusing agent. This fully melted material is cooled to a hardened state and shipped as a semi-finished product throughout the Roman world. Subsequently small furnaces can then be used for re-heating the raw glass to a molten state which is used for blowing the plastic material into various forms of finished products. In using pre-melted materials (raw glass) the compositions of objects produced at a given production site will reflect the original raw glass itself.

Compositions and chemical variations of previously published chemical analyses for glass workshops

If we can establish a plausible trajectory for one example from an Egyptian raw glass production site to France and the deposit of blown glass objects made from this material, can one find regular relations over time in the provenance of raw glass products elsewhere in the Roman Empire production sites?

In order to establish the patterns of supply and use of raw glass to form blown glass objects we compare the chemical compositions of glass droppings and un-finished products from seven workshops with compositions of Roman glass objects found in excavations of parts of several cities in present day France and Germany. These data are used as an example of the type of variations possible for a given large site of glass consumption. The chemical analyses used here are from general archaeological excavations of urban sites reported by Velde (1990), Velde and Sennequier (1985) and Aerts et al. (2003). These analyses are from the 1-4th century finds from Rouen (France), 2-6th century from Koln (Germany), 2-5th century from Maastricht (Belgium).

Analyses of material from specific workshops producing blown glass objects in France are found in Velde and Gendron (1980) at Saintes France; Velde and Hoschuli-Gysel (1996) Saintes, France and another site at Saintes France Velde (1990), two sites in the Argonne forest area of Eastern France, and finally a site in Lyon, France (Nenna et al., 1997). Workshop material from two sites in the Near East, at Qumran (Aerts et al., 2000) and Jalame (Davidson Weinberg, 1988) is also considered. The Jalame 4th century site operated over a 40 years period and Qumran 1st century site operated for a 70 years period.

Using the same chemical variables of sodium, calcium and aluminium to describe the variations in fusing component and sand source, one can investigate the variations of glass material used to produce various objects. Figure 5 shows the fusing agent (sodium) – sand (calcium) variations for the seven workshops.

The patterns of composition are quite varied, ranging from a rather significant dispersion for one of the the 2-3rd century Saintes workshop compositions, to slightly dispersed compositions into two rather well defined groups for the Near Eastern Jalame site and to rather small variations in other sites. The Near East Qumran site seems to have two basic compositions present. The two Argonne sites seem to have very similar compositional ranges indicating the same supplier for these workshops.

If we consider the variations in sand composition (Ca, calcium and Al, aluminium oxide) shown in Figure 6, it appears that the components are much more tightly grouped in some cases, but the tendencies to find different sources are still present. The Saintes FEN workshop samples show considerable variations in composition as previously seen in sodium-calcium coordinates.

When the compositions are tightly grouped for a given workshop one could suspect the existence of the same supplier of raw glass. When the compositions are more dispersed it is possible to have different sources of raw glass over the period of its existence, either quite varied (FEN) or restricted into a few distinct groups such as the Qumran site samples. However, the variations observed for a given workshop are not anywhere near the dispersion found for all Roman glasses compared here which represent a wide range in time for European glass samples. In order to assess the variations possible for a more restricted use area, we can compare these workshop variations with those for individual urban excavation sites such as Köln, Rouen or Maastricht. Here different patterns emerge for different cities. Samples from Köln have a rather large dispersion of sand component compositions for both early and later glass finds (2-3rd and 4-6th centuries). Samples from Maastricht, a smaller urban center, seem to have a smaller scatter in compositions perhaps indicating a smaller number of workshops making glass objects which supplied the needs of the city. Samples from Rouen also show a significant scatter for the sand composition indicators.

It seems then that the scatter in composition indicates the diversity of sources of objects manufactured and transported to the city for use and eventual discard which could be expected when considering the total variations in the different workshop material discussed above. However regional (city) differences can be seen.

Discussion

Initially one must remember the advantages of using raw glass at a glass blowing production site. One main advantage is that the need to use recuperated glass is eliminated allowing the use of a melt material of identical technical qualities for the production of blown objects of consistent characteristics. It made life much easier for the glass blower. Further the coloring characteristics were constant. Although Roman glass is generally of similar compositions, the color tint of clear glass is not, ranging from slightly bluish to yellow brown to un-colored. Secondly, the use of ready to use glass for blowing reduced the capital investment in furnaces which are necessary for glass making itself.

Given the very great amount of glass produced and the long period of production, one can imagine that numerous ateliers were set up to produce the raw glass sent to users. The constant content of impurities due the soda source, magnesia and potash both near or below one percent of the glass, indicates a similar source of the fusing agent. Values of calcium and alumina seem more variable indicating that the sand sources were not entirely identical over time. Thus small changes in sand source and the ratio of fusing agent (soda) and sand changed the physical properties of the molten glass to a small but most likely appreciable extent. These variations and their consequences are outlined by Stern (2008).

If we consider the chemical variations of objects found within a glass blowing production site from the seven sites investigated above, it seems that in some cases there can be relatively little change in composition, being centered on one or perhaps two types of raw glass sources coming from the Near East. Production sites making blown glass objects geographically near those of the raw glass manufacture or those in far away, for example in present-day France, will show the same types of compositional variations. Of interest then is the close similarity of compositions for the two production sites in the Argonne forest France which seem to have had the same supplier. This suggests that there was a relation between supplier and use site. The same observations can be made for other manufacturing workshops which used the very similar raw glass materials supplied over large geographic areas in the Empire. Such relations could change with time of course. However, similarity of composition at a given site operating for several decades in certain cases argues for a continued relation between supplier of raw glass and manufacturing consumer in the industrial chain. Further, this implies a commercial relation between the supplier and consumer, which would necessitate a transmission of commercial information (orders and shipments) either transmitted directly or more likely through an intermediary dealer. Since the raw glass is very similar in aspect, each source had to be labelled in one manner or another so that intermediaries could keep track of it in the redistribution process. The simple fact that the raw glass was often shipped by boat to the other side of the Mediterranean indicates that it had to be unloaded, stored and re-shipped, via river boat up the Rhone river to Lyon for instance, and hence, again unloaded and re-dispatched via land transport to its final destination. This implies a strong organisation of commerce and transport in general for the raw glass products. In the Embiez ship wreck material the presence of raw glass of one composition and blown objects of the same as well as different composition suggests that an individual ship moved material for different purposes with specific orders for furnishing products of different sorts.

However dispersed compositions for some workshops suggest that at those sites varied sources of raw glass were used and that as a result there was not a direct contact with the producer but one of a general supplier or center of distribution. Thus there was not a desire to have the same material to blow the glass objects produced at these sites. Perhaps even recuperated used glass objects were incorporated into the melt used to make new objects.

Conclusion

The above analysis underscores the idea that each glass blowing workshop throughout the Roman Empire could very well have a preference for a type of raw glass material which was used by specific workmen it employed. The interesting idea is that perhaps workshops could in fact order materials from specific producers of raw glass in Egypt or the Near East and have them shipped over the rather great distances of the Empire. This would mean that very easy and continued communication was possible in every day commercial and manufacturing ventures. Production sites in the Near East as well as northern France seemed to have been able to draw on this communications network.

More intriguing perhaps is the concept of a possible centralization into a type of monopoly for the production of raw glass. The large amount of glass produced on the Levantine coast over a long period suggests a strong organisation of manufacturing effort and more importantly a centralized distribution system for raw glass. A small but distinct variation of glass compositions for objects found over the Empire suggests that the raw glass was produced by smaller units which each gave small variations in composition one compared to the other. This organisation of production would be similar to that found for the Terra Sigilata export pottery produced in major production sites by a large number of individual ateliers in Gaulic France at Lezoux or La Graufesenque for example (see Jackson and Greene, 2008 for example). One can conceive of a system of organizing the production of individual producers which centralized product distribution according to orders placed from various parts of the Empire. Who owned or directed the organized system is another problem to solve. However the concept of producing a superior semi-finished product and getting it to a vast market according to demand is rather novel. A de facto monopoly was formed due to the superior qualities of the product which allowed direct production of a finished product from semi-finished glass. The major advantage was that there was no need for capital investment and maintenance of furnaces and procurement of raw products to produce the glass used in the production of the blown objects. This problem of procurement of raw materials was to prove to be a stumbling block in glass production posterior to the Roman period where individual production sites scattered over the former Empire needed to gather the raw materials, sand and alkali ash, to produce frit in a special furnace, as well as to find sufficient cullet either produced and re-used on site or gathered from refuse in urban areas and combine these materials to produce the molten glass for blowing. The problem was sufficiently great as to reduce primary glass production to almost nothing. All of these operations necessitate careful and costly measures to produce a consistent glass melt with regular properties. The Roman system proposed a guaranteed product of standard qualities which could be used at a rather low investment to produce a finished product. This flexibility of production, low cost of installation, surely explains in part the widespread use of glass in Roman times for windows, shipping containers and table ware as well as luxury goods.

In this case innovation was accomplished through the re-organisation of the glass making process, breaking it into specific steps; extraction of raw components of sand and fusing agent, production of glass and the last step of producing a glass vessel. By dissociation of the steps of production it was possible to control the quality of the glass material by using the same pure materials and to use this standard, superior material to produce objects according to their need at local sites. Further this allowed the transport of fragile objects to be much more limited and close to the final market or consumption site. Here innovation was shown by a new organisation of the industrial process.

Bruce Velde

Annex

| Na2O | MgO | Al2O3 | SiO2 | P2O5 | K2O | CaO | TiO2 | FeO | MnO | |

|---|---|---|---|---|---|---|---|---|---|---|

| Pierrepont | ||||||||||

| 6 | 18,55 | 0,35 | 1,67 | 72,43 | 0,13 | 0,42 | 5,56 | 0,2 | 0,1 | 0,25 |

| 7 | 18,65 | 0,49 | 1,9 | 72,12 | 0,18 | 0,49 | 5,33 | 0,05 | 0,07 | 0,38 |

| 8 | 20,21 | 0,52 | 2,25 | 70,91 | 0 | 0,48 | 4,9 | 0 | 0,16 | 0,27 |

| 9 | 19,49 | 0,6 | 2,22 | 70,33 | 0,21 | 0,47 | 5,5 | 0,05 | 0 | 0,63 |

| 10 | 18,83 | 0,82 | 2,35 | 70,54 | 0,41 | 0,7 | 5,58 | 0 | 0 | 0,63 |

| 5 | 19,63 | 0,74 | 2,01 | 72,01 | 0 | 0,48 | 4,5 | 0 | 0,05 | 0,38 |

| 4 | 19,41 | 0,69 | 1,99 | 71,47 | 0,17 | 0,31 | 5,13 | 0,03 | 0 | 0,3 |

| 3 | 18,37 | 0,5 | 2,38 | 69,52 | 0,22 | 0,7 | 6,16 | 0,12 | 0,92 | 0,76 |

| 2 | 20,04 | 0,45 | 1,76 | 71,66 | 0 | 0,41 | 5,33 | 0 | 0,05 | 0 |

| 13 | 20,28 | 0,48 | 1,89 | 72,1 | 0,07 | 0,49 | 4,62 | 0 | 0,2 | |

| 12 | 19,62 | 0,42 | 1,91 | 71,84 | 0,01 | 0,44 | 5,47 | 0 | 0,3 | |

| 11 | 20,85 | 0,26 | 1,78 | 72,15 | 0 | 0,5 | 4,56 | 0 | 0,04 | |

| 14 | 18,64 | 0,49 | 1,65 | 73,44 | 0,27 | 0,38 | 4,98 | 0 | 0,26 | |

| 15 | 20,18 | 0,47 | 1,76 | 72,2 | 0,15 | 0,44 | 4,5 | 0 | 0,31 | |

| 16 | 22,29 | 0,32 | 1,92 | 70,14 | 0,27 | 0,46 | 4,19 | 0,15 | 0,26 | |

| Arcis/Aube | ||||||||||

| 80 | 21,07 | 0,57 | 1,66 | 71,21 | 0 | 0,51 | 4,62 | 0,17 | 0,45 | 0 |

| 60B | 19,94 | 2,01 | 2,01 | 72,07 | 0,46 | 0,56 | 6,33 | 0,28 | 0,27 | 0,22 |

| 75 | 19,1 | 0,59 | 1,82 | 69,22 | 0,23 | 0,47 | 5,19 | 0 | 0,13 | 0 |

Table 1. Chemical compositions of glasses from eastern France in weight percent. Analyses done by electron microprobe. Arcis-sur-Aube samples reported in Cabart (2004) and Pierrepont samples reported in Cabart (2005).

The chemical analyses were performed on small polished glass fragments (2-3 mm diameter) using a quantitative diode analyser on a scanning electron microscope (University of Poitiers, ERM facilities). Most values are of a reproducbility to within 0.1 % of the oxide reported.

References Cited

- Aerts A., Velde B. and Janssens K. (2003),

"Change in silica sources in Roman and post-Roman glass", Spectrochimica Acta B, 659-667. - Aerts A., Jannsens K., Velde B., Adams F. and Wouters H. (2000),

"Analysis of the composition of glass objects from Qumrân, Israel and comparison with other Roman glass from western Europe", La Route du Verre, Travaux de la Maison d'Orient Méditerranéen 33, 113-122. - Brill R. H. (1999),

Chemical Analyses of Early Glass, Vol. II, Corning Museum, 553 p. - Cabart H. (2004),

« Deux tombes privilégiées d'Arcis-sur-Aube », Bulletin de l'AFAV, 11-15. - Cabart H. (2005),

« Les verres gallo-romains de Pontpierre (Moselle) », Bulletin de l'AFAV, 18-22. - Davidson Weinberg G. (1988),

Excavations at Jalame, University of Missouri Press, 378 p. - Dussart O. and Velde B. (1990),

« La composition de verres hellénistiques en Jordanie et Syrie du Sud », Syria, 68, 687-693. - Foy D., Vinchy M. and Picon M. (2000),

« Lingots de verre en Méditerranée occidentale (IIIe siècle av. J.-C. - VIIe siècle ap. J.-C.) », Annales du 14e Congrès de l'AIHV, 51-57. - Foy D., Thirion-Merle V. and Vichy M. (2004),

« Contribution à l'étude des verres antiques décolorés à l'antimoine », Revue d'Archéométrie, 28, 169-177. - Foy D., Jézégou M.-P. and Fontaine S. (2005),

« La circulation du verre en Méditerranée au début du IIIe siècle : le témoignage de l'épave Ouest-Embiez dans le sud de la France (fouilles 2001-2003) », Annales du 16e Congrès de l'AIHV, 122-126. - Jackson M. and Greene K. (2008),

"Ceramic production", 496-519, in J. P. Oleson ed., Engineering and Technology in the Classical World, Oxford University Press, 865 p. - Nenna M.-D., Vichy M. and Picon M. (1997),

« L'atelier de verrier de Lyon du Ier siècle après J.-C., et l'origine des verres romains », Archéométrie, 21, 81-87. - Nenna M.-D., Picon M. and Vichy M. (2000),

« Ateliers primaires et secondaires en Égypte à l'époque gréco-romaine », La Route du Verre, Travaux de la Maison d'Orient Méditerranéen 33, 97-112. - Nenna M.-D., Picon M., Thirion-Merle V. et Vichy M. (2005),

« Ateliers primaires du Wadi Natrun : nouvelles découvertes », Annales du 16e Congrès de l'AIHV, 59-63. - Stern M. (2008),

"Glass production", 520-550, in J. P. Oleson ed., Engineering and Technology in the Classical World, Oxford University Press, 865 p. - Toutain J. (1927),

L'Économie antique, La Renaissance du Livre, Paris, 439 p. - Velde B. (1990),

"Alumina and calcium oxide content of glass found in western and northern Europe, first to ninth centuries", Oxford Journal of Archaeology, 9, 105-117. - Velde B. and Sennequier G. (1985),

"Observations on the chemical compositions of several types of gallo-roman and frankish glass production", Annales du 9e Congrès de l'AIHV, Nancy, 127-147. - Velde B. and Gendron C. (1980),

"Chemical composition of some gallo-roman glass fragments from Central Western France", Archaeometry, 22, 183-188. - Velde B. and Hoschuli-Gysel A. (1996),

"Correlations between antimony, manganese and iron content in Gallo-roman glass", Annales du 13e Congrès de l'AIHV, 185-192.